The handheld metal laser welder has become one of the most transformative tools in modern manufacturing, fabrication, and repair work. Unlike traditional welding methods, this technology delivers unmatched precision, speed, and control—making it ideal for both small-scale workshops and industrial environments. The growing adoption of laser welding is reshaping how metals are joined, repaired, and finished in industries such as automotive, aerospace, electronics, and custom fabrication.

Laser welding is not a new concept, but the handheld metal laser welder has changed how this technology is applied in real-world operations. It merges portability with the powerful performance of laser systems, allowing operators to move freely while maintaining consistency in the welding process. This shift from fixed, bulky laser systems to compact handheld devices enables companies to streamline their processes, improve product quality, and reduce operational costs.

Understanding How a Handheld Metal Laser Welder Works

At its core, a handheld metal laser welder functions by directing a focused laser beam onto the surface of metals to create a high-temperature zone that fuses the materials together. This method relies on the precision of the laser, which allows deep and narrow welds with minimal distortion.

The energy from the laser beam is absorbed by the metal, rapidly melting the surface and allowing it to bond with adjoining material. The result is a clean, durable joint with minimal spatter or deformation. Because the welder uses light energy instead of an electrical arc or filler materials, it offers a clean and consistent finish that requires less post-processing.

This advanced welding technique also supports a variety of metals, including stainless steel, aluminum, copper, titanium, and carbon steel. Whether used for thin sheet metal or thick industrial components, the handheld metal laser welder adapts easily to different material types and thicknesses.

The Role of Handheld Laser Welding in Modern Industry

Across industries, companies are integrating handheld metal laser welders to meet increasing demands for precision, speed, and automation. Manufacturers that rely on metal components now see this technology as an essential part of their workflow.

In automotive manufacturing, it is used to assemble intricate body components and structural parts where accuracy is vital. In aerospace and defense sectors, laser welding ensures high-strength joints that can withstand extreme conditions. Electronics manufacturers use it to connect delicate metal parts without introducing excess heat that could damage sensitive components.

Even small and medium workshops are adopting handheld laser welders for maintenance, custom projects, and prototype development. The ease of use allows operators to perform high-quality welds with minimal training, enabling greater flexibility and reducing dependency on highly specialized labor.

Productivity and Efficiency in Welding Operations

Efficiency is one of the strongest reasons why the handheld metal laser welder has become a popular choice for manufacturers. Its high energy concentration allows rapid fusion, reducing welding time compared to conventional methods. The minimal heat-affected zone ensures that materials retain their structural integrity, even during intensive production cycles.

Another benefit is the reduction in rework and post-processing. Traditional welding often requires grinding, polishing, or cleaning to remove oxidation or spatter. With laser welding, joints are clean, precise, and visually appealing right from the start. This helps businesses optimize their workflow and deliver finished products faster.

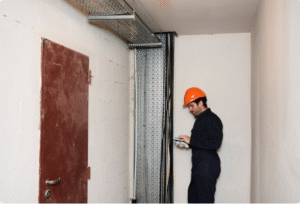

Many companies also value the handheld welder’s mobility. Operators can easily move the device to reach complex geometries or confined areas, something that fixed welding systems cannot achieve. This makes it particularly useful for onsite repairs, custom metal fabrication, and installation projects.

Adapting to Various Materials and Applications

A handheld metal laser welder supports a broad range of applications across different material types. In the case of stainless steel, it delivers smooth, corrosion-resistant joints ideal for kitchenware, medical equipment, and construction components. For aluminum, the technology provides a clean bond without cracks or porosity, often seen in traditional welding.

Copper and brass components benefit from laser welding’s precise energy control, ensuring consistent results even with materials that conduct heat quickly. Industries dealing with reflective metals—often challenging for arc or TIG welding—can now achieve strong, uniform welds without extensive preparation.

The handheld design also enables operators to weld irregular shapes and complex designs. From artistic metalwork to precision industrial assemblies, laser welding provides flexibility while maintaining structural accuracy and surface finish quality.

Safety and Environmental Considerations

In addition to performance, the handheld metal laser welder promotes a safer and cleaner working environment. Since it does not rely on consumable materials like filler rods or flux, it produces minimal fumes and waste. The process generates less heat and virtually no spatter, reducing the risk of burns and contamination.

Laser welding systems are also energy-efficient compared to traditional arc-based techniques. They consume less electricity and have fewer emissions, contributing to a lower environmental footprint. For facilities aiming to meet sustainability standards or reduce operational hazards, handheld laser systems are a practical investment.

Integration with Modern Manufacturing Systems

With the rise of automation and Industry 4.0 technologies, handheld metal laser welders fit seamlessly into digital manufacturing systems. Many modern units come equipped with intelligent controls, user-friendly interfaces, and preset parameters for various metals. This ensures consistent performance regardless of operator skill level.

Furthermore, laser welding equipment can be paired with robotic systems for semi-automated or fully automated operations. The combination of precision, data-driven control, and high-speed performance enables manufacturers to achieve reliable results with minimal supervision.

The Growing Demand for Handheld Laser Welding

The global market for laser welding equipment is rapidly expanding, and handheld devices represent one of its fastest-growing segments. As industries shift toward cleaner, faster, and more reliable production methods, demand for these systems continues to increase.

Companies are recognizing the long-term cost efficiency offered by handheld metal laser welders—not only from reduced labor and maintenance but also from improved product quality and reduced material waste. Their compact form factor and plug-and-play operation make them ideal for both large manufacturing setups and small repair shops.

Practical Use Cases Across Sectors

-

Automotive Repair and Assembly – Used for welding car body panels, exhaust systems, and frames with minimal heat distortion.

-

Aerospace Components – Ensures lightweight, durable joints for aircraft structures and fuel systems.

-

Jewelry and Fine Metalwork – Allows detailed repairs and precise joining without damaging delicate designs.

-

Fabrication Workshops – Provides flexibility for custom projects, prototypes, and structural work.

-

Maintenance and Repair Operations – Ideal for fixing machinery, tools, and metal structures directly on-site.

These applications highlight the versatility and effectiveness of handheld laser welders in modern fabrication and repair settings.

Final Thoughts

The handheld metal laser welder represents a major advancement in metal joining technology. It bridges the gap between industrial precision and operator flexibility, making high-quality welding accessible across multiple sectors. From mass production lines to custom fabrication shops, this tool has redefined how professionals approach metalwork.

Its ability to produce clean, durable joints with minimal effort and environmental impact ensures its place as a cornerstone of future manufacturing. As industries continue to evolve, the handheld laser welder will remain an essential instrument—driving innovation, precision, and efficiency in every weld.