In today’s evolving industrial world, handheld metal laser welding has become a significant force in transforming how professionals work with metal. This technique is reshaping fabrication standards, production speed, and finishing quality across countless sectors. Its influence is visible in modern workshops, large factories, repair centers, custom manufacturing units, and even specialized artistry studios where precision is essential. As industries progress toward cleaner, more refined, and more efficient production practices, handheld solutions are gaining remarkable attention because they offer mobility, adaptability, and consistent performance without the restrictions of large-scale stationary machinery.

The growing emphasis on craftsmanship and refined output has made handheld metal laser welding a preferred choice for industrial specialists. It is now part of workflows where delicate joints, fine details, or complex shapes need attention. Whether used for thin materials, thick components, intricate designs, or rapid repair, this welding method adapts well to varying requirements. For fabricators and technicians, this flexibility can be a turning point in meeting rising customer demand for fast turnaround projects with fine finishes.

One of the most noticeable changes brought forward by this innovation is how it simplifies processes that were once considered difficult or time-consuming. Traditional equipment often required multiple preparation stages, lengthy adjustments, or extensive training before a worker could comfortably operate the system. However, the shift toward portable solutions has made metalworking more approachable for both experienced welders and newcomers entering the field. This change has not only improved productivity but has also opened opportunities for businesses to expand services without major disruptions.

The relevance of handheld metal laser welding also lies in its ability to support modern design preferences. Today’s clients and industries favor clean lines, refined edges, and smooth joints that align with contemporary aesthetic standards. Products ranging from architectural structures to furniture, automotive components, decorative pieces, machinery parts, and metal frameworks rely on precise connections to maintain both beauty and strength. This welding method supports these expectations by offering consistent control that enhances the final appearance of welded sections. Smooth transitions, minimal marks, and neat lines contribute significantly to the overall appeal of finished products.

Beyond aesthetics, the functionality of welded components is equally important. Industrial pieces must endure pressure, load, environmental exposure, and long-term use. Consistent and reliable joints ensure that structures and devices operate safely and efficiently. In many manufacturing environments, customers demand durable outcomes without delays. This is where handheld equipment shines, helping technicians create reliable metal bonds in a shorter timeframe. Its adaptability plays a key role in meeting these expectations, especially when dealing with a variety of metals such as stainless steel, aluminum, carbon steel, or specialized alloys.

The competitive industrial environment also pushes manufacturers and service providers to adopt tools that support versatile application methods. With handheld metal laser welding, workers can switch between different tasks with minimal interruption. Whether filling gaps, repairing damaged sections, crafting new designs, or assembling components, the flexibility of a handheld solution allows operators to deliver consistent performance. This agility is particularly valued in workshops where project types change daily or even hourly.

Another major factor contributing to its widespread use is the way it responds to modern production speed requirements. As global marketplaces expand, customers expect faster delivery without compromising quality. Delays in manufacturing can significantly affect business relations, revenue, and brand reputation. Portable welding equipment helps companies keep up with tight schedules, high-volume orders, or urgent custom requests. The ability to move freely around complex structures or large pieces adds another layer of efficiency that stationary systems cannot easily provide.

Beyond industrial manufacturing, handheld metal laser welding has also found its place in artistic metalwork. Sculptors, designers, and custom metalworkers appreciate the control it allows when creating fine details or merging delicate shapes. Whether crafting ornamental gates, decorative wall art, jewelry components, or one-of-a-kind installations, this welding technique supports creativity by allowing welders to execute ideas with precision. It has become particularly popular in workshops where personalized or hand-crafted pieces are the main focus.

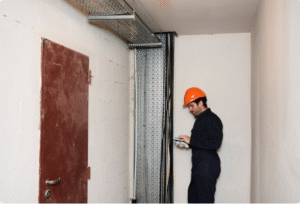

Repair and maintenance teams have also benefited from the convenience of portable welding systems. Instead of transporting large machinery or heavy parts to specialized repair centers, technicians can carry the handheld equipment directly to the site. This is especially useful in industries such as construction, automotive repair, marine engineering, agricultural machinery maintenance, and industrial equipment servicing. Being able to perform on-site repairs minimizes downtime, reduces project interruptions, and helps businesses resume operations quickly.

Another aspect that attracts technicians is how easily handheld metal laser welding integrates into different workflows. Operators can combine it with cutting, shaping, grinding, or polishing tasks without needing major setup changes. This smooth transition supports streamlined productivity and helps maintain consistent quality throughout the fabrication process. Workshops with limited space also appreciate the compact nature of handheld systems, which offer powerful performance without occupying large areas.

Training is another area where this technique has made a noticeable impact. Traditional welding often requires extended learning periods before new welders can deliver professional-level results. The introduction of handheld laser tools encourages smoother learning experiences by offering clear visibility, comfortable handling, and manageable control. As industries continue to face a shortage of skilled welders, tools that support easier training become essential for long-term business sustainability.

In sectors where cleanliness and precision are critical, such as food processing equipment, medical device manufacturing, electronics casings, and laboratory tools, this welding method is widely appreciated. It ensures smooth finishing that prevents contamination build-up and maintains product hygiene. These industries rely heavily on flawless surfaces because even minor defects can affect functionality or compromise safety. Handheld tools assist technicians in achieving refined output that aligns with strict industry standards.

The development of handheld metal laser welding technology has also supported sustainability efforts. More companies are adopting responsible manufacturing processes that reduce excessive waste, minimize rework, and optimize energy consumption. This technique contributes by creating clean welds that require limited post-processing. The reduced need for filler materials or extensive grinding allows businesses to lower resource consumption while still maintaining high-quality results.

As industries progress, customer expectations also advance. People now look for products that reflect both technical excellence and visual refinement. Whether it’s a metal staircase in a modern home, a custom car part, a stainless-steel kitchen setup, or a structural component for machinery, the finishing must meet both practical and aesthetic standards. This welding method supports such expectations by providing a level of control and consistency that enhances customer satisfaction.

Companies looking to expand their service offerings often adopt handheld metal laser welding to stay competitive. It allows them to take on projects they previously couldn’t handle due to equipment limitations. This expansion not only attracts new clients but also increases long-term growth opportunities. As the demand for custom fabrication and rapid production increases, businesses equipped with portable welding systems find themselves better positioned in the marketplace.

Manufacturers supplying these tools continue to refine their designs with improved ergonomics, stable performance, and refined control mechanisms. This ongoing development ensures that welders—whether working in small workshops or large industrial environments—can enjoy a dependable and efficient experience. As a result, this technique is now recognized as a reliable standard in modern metal fabrication.

Overall, the rise of handheld metal laser welding reflects a broader movement toward flexible, efficient, and visually refined metalworking solutions. Across industries, craftsmanship continues to evolve, and the demand for seamless results grows stronger. Professionals are increasingly searching for tools that support precision, mobility, and steady performance in a wide variety of applications.

Final Thoughts

The growing influence of handheld metal laser welding marks a significant shift in how industries approach fabrication, repair, design, and production. It represents a modern solution for businesses seeking adaptability, refined craftsmanship, and reliable performance across a wide range of metalworking tasks. As global standards continue to rise, this technique stands as a practical and forward-moving choice for professionals looking to deliver exceptional results.