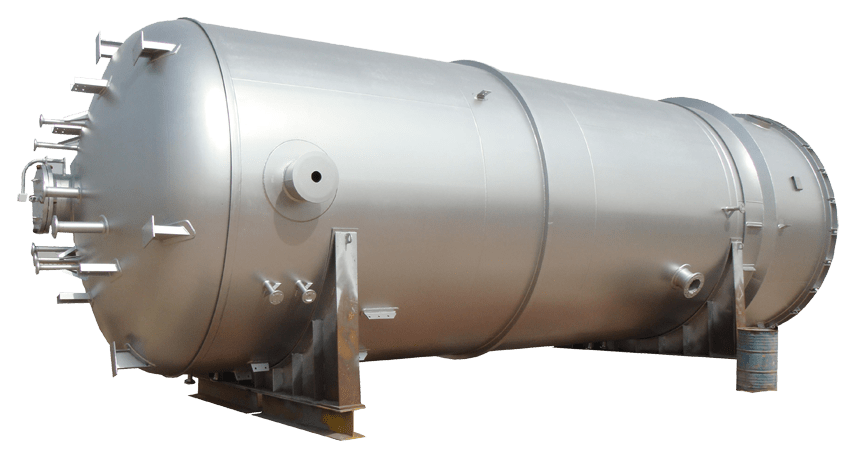

pressure vessel tank

In industries like oil & gas, chemicals, food processing, pharmaceuticals, and power generation, pressure vessels are the backbone of safe and efficient operations. These vessels handle extreme pressures and temperatures, making them one of the most critical components in any processing plant.

But when it comes to sourcing them, not all manufacturers are created equal. Partnering with a certified pressure vessel manufacturer ensures safety, compliance, and long-term value for your investment. In this blog, we’ll explore the top 5 reasons why certification matters and why choosing the right partner is crucial for your business.

1. Guaranteed Safety and Compliance

Pressure vessels operate under conditions that can be dangerous if not handled properly. Failures due to poor design, low-quality materials, or improper fabrication can lead to severe accidents, financial losses, and reputational damage.

A certified manufacturer adheres to international standards such as:

-

ASME Section VIII (Boiler & Pressure Vessel Code)

-

PED (Pressure Equipment Directive)

-

ISO standards

This guarantees that your vessel is designed, manufactured, and tested to withstand the required pressures safely. Partnering with a certified provider means peace of mind—knowing your equipment meets all regulatory and safety requirements.

2. Superior Quality Materials and Workmanship

Not all pressure vessels are the same. The difference lies in the quality of raw materials, precision of fabrication, and attention to detail.

Certified manufacturers are required to:

-

Source materials from approved suppliers.

-

Maintain traceability for every component used.

-

Employ skilled welders and fabricators with certifications.

-

Conduct rigorous inspections at every stage of production.

This ensures that your pressure vessel tank is built for durability, reliability, and long service life—even in the most demanding environments.

3. Cost-Effective in the Long Run

At first glance, uncertified or low-cost manufacturers may seem attractive. However, hidden risks such as poor durability, frequent repairs, or even complete vessel failure often outweigh the short-term savings.

With a certified partner, you benefit from:

-

Reduced downtime thanks to high-quality builds.

-

Lower maintenance costs due to superior workmanship.

-

Longer vessel lifespan, maximizing return on investment.

In essence, investing in a certified manufacturer ensures that your upfront costs translate into long-term savings.

4. Access to Engineering Expertise and Customization

Every industry and plant has unique requirements. A standard off-the-shelf vessel may not always fit your process.

Certified manufacturers bring not just equipment but also engineering expertise. They work with you to:

-

Design vessels customized for your operating pressures, temperatures, and capacities.

-

Recommend the best materials for corrosion resistance and durability.

-

Provide detailed CAD drawings and 3D modeling for approval before fabrication.

-

Ensure vessels integrate seamlessly into your plant layout and systems.

This level of customization and technical collaboration is only possible with experienced and certified professionals.

5. Strong After-Sales Support and Documentation

Certified manufacturers don’t just deliver a product—they provide a complete support package. This includes:

-

Comprehensive documentation for compliance audits and inspections.

-

Warranty and guaranteed performance assurances.

-

Training for operators and maintenance staff.

-

Quick access to spare parts and repair services.

Partnering with a reliable pressure vessel supplier also means you have ongoing support throughout the lifecycle of the equipment, ensuring your operations run smoothly and safely.

Why Partnering with a Certified Manufacturer is a Business Advantage

In industries where downtime is costly and safety is non-negotiable, your choice of pressure vessel manufacturer can directly impact productivity, compliance, and profitability.

By choosing a certified manufacturer, you’re not just buying a piece of equipment—you’re investing in:

-

Risk Reduction: Safer operations and fewer compliance issues.

-

Operational Efficiency: Reliable equipment that minimizes downtime.

-

Business Growth: The confidence to scale with world-class infrastructure.

Final Thoughts

Pressure vessels are critical assets, and choosing the right partner is one of the most important decisions for any plant operator or business owner. A certified manufacturer brings safety, quality, cost savings, engineering expertise, and lifelong support—all of which directly contribute to your success.

Whether you’re setting up a new facility or upgrading existing infrastructure, partnering with a certified manufacturer is the smartest way to secure a safe and profitable future.

If you’re ready to invest in world-class equipment, now is the time to explore certified solutions that meet your industry’s highest standards.