Artificial operations in the oil painting and gas sector calculate heavily on dependable, durable, and environmentally biddable systems to handle fluids, vapors, derivations, and heat exchange demands. Among the most pivotal factors that shape performance and safety are heat exchangers and environmental tanks designed for effective separation and constraint. This is where systems like the jatco shell and tube outfit and the protean 10 gallon environmental tank gain significant attention across the sector. The rising demand for better environmental operation has pushed companies to explore advanced results similar as jatco environmental tanks, specialized jatco tanks, and the extensively enforced btex eliminator system, which inclusively enhance functional trustability. In moment’s period of heightened nonsupervisory fabrics and sustainability pressures, associations must borrow systems that meet strict environmental compliance for oil painting and gas, maintain optimal product affair, and align with the growing need for pollution control outfit for oil painting and gas.

The part of Heat Exchangers in Oil and Gas Operations

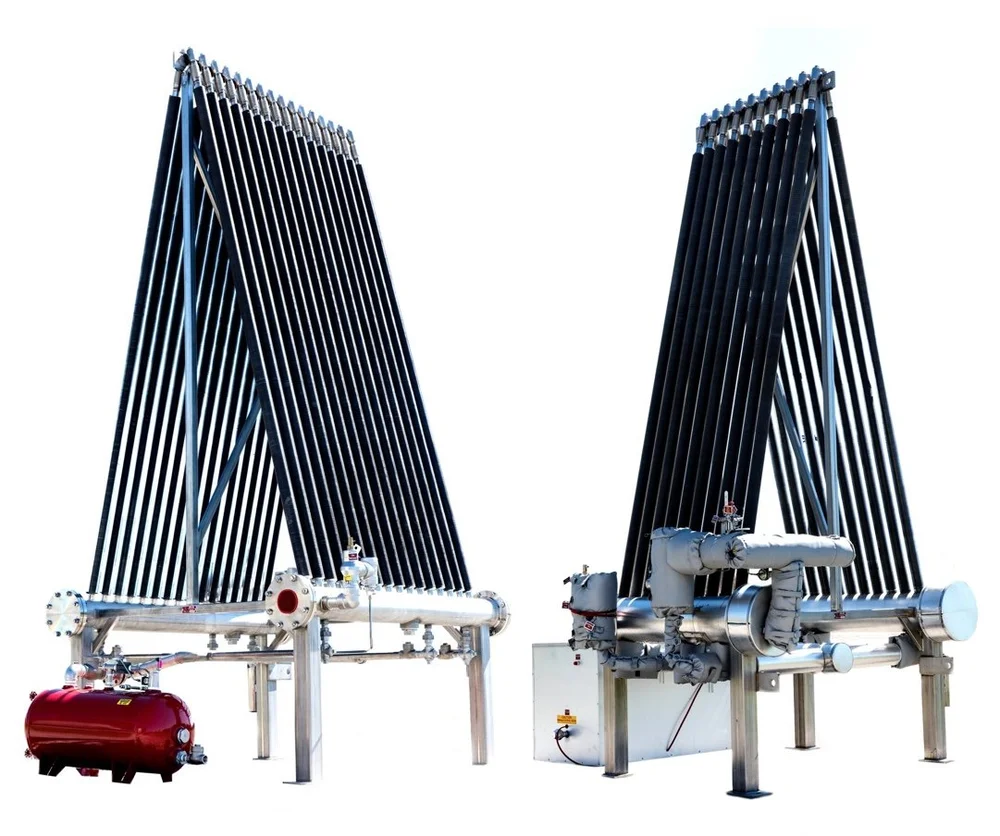

Heat exchangers play an essential part in thermal regulation, process stability, and effective product overflows. The jatco shell and tube design has come a favored choice because of its high thermal transfer effectiveness, robustness, and rigidity to extreme artificial conditions. As companies expand their resource operation strategies, results similar as the 10 gallon environmental tank complement heat exchangers by furnishing secure constraint for fluids associated with cooling, heating, or chemical processing. These systems uphold best- in- class engineering norms and support a broader shift toward enhanced environmental sustainability in oil painting and gas assiduity operations. The integration of environmental constraint with high- capacity heat exchangers is decreasingly vital for businesses that must maintain compliance while seeking to ameliorate productivity and reduce environmental impact.

Why Shell and Tube Systems Are Still the Assiduity Standard

The long- standing dominance of the jatco shell and tube system is largely attributed to its structural integrity and capability to handle oscillations in temperature and pressure. These exchangers are designed for heavy- duty cycles, making them ideal for upstream, midstream, and downstream operations. When integrated with advanced environmental systems like a 10 gallon environmental tank, drivers gain more precise control over fluid operation. The combination delivers harmonious performance, minimized leakage pitfalls, and provides a strong foundation for meeting environmental compliance for oil painting and gas installations. also, with environmental regulations getting decreasingly demanding, companies need sturdy systems that support effective contaminant separation, bettered capacity running, and streamlined conservation. This is why jatco environmental tanks are being espoused across drilling pads, chemical treatment zones, and vapor scrubber systems within oilfields.

Significance of Environmental Tanks in functional Compliance

Environmental tanks serve as pivotal constraint points, especially when handling produced water, chemical complements, hydrocarbon vapors, or vapors removed by a btex eliminator system. results similar as the 10 gallon environmental tank give a compact, effective way to manage fluids safely in zones where space and nonsupervisory parameters limit the use of larger constraint systems. erected to integrate with other factors like the jatco shell and tube exchanger, these tanks enhance safety by minimizing pitfalls related to tumbles andcross-contamination. They also support the broader charge of pollution control outfit for oil painting and gas, especially where field installations operate within strict emigration- control fabrics. Through the operation of robust environmental tanks, companies can apply safer disposal, bettered constraint capacity, and compliance with state and civil guidelines.

Enhancing System continuity and effectiveness Through Advanced Engineering

Continuity is a critical factor when choosing heat exchangers and tanks for oil painting and gas operations. The jatco shell and tube excels in performance life, taking minimum time-out and immolation dependable temperature control under high- stress conditions. Used together with outfit like a 10 gallon environmental tank, these systems deliver bettered functional measures and enhanced protection. With ultramodern engineering ways, jatco tanks are specifically designed for resistance against erosion, temperature axes, and chemical exposure. The combination of these factors plays directly into optimizing product processes, reducing expensive repairs, and creating structure able of supporting enhanced environmental sustainability in oil painting and gas assiduity objects. also, these advancements contribute toward stronger safety mechanisms within processing and storehouse installations.

How BTEX Elimination Improves Worker and Environmental Safety

The relinquishment of the btex eliminator system is transubstantiating the way oil painting and gas installations handle unpredictable organic composites( VOCs). Benzene, toluene, ethylbenzene, and xylene pose serious hazards if not managed rightly. The capability of a btex eliminator system to mite or contain vapors ensures that emigrations are minimized and workers are shielded from dangerous exposures. The jatco shell and tube exchanger works seamlessly within process circuits where temperature regulation is essential for BTEX junking effectiveness, while the 10 gallon environmental tank assists in holding derivations safely. This union of technologies supports both functional effectiveness and compliance, icing businesses meet crucial norms associated with environmental compliance for oil painting and gas. With regulations tensing worldwide, the relinquishment of advanced BTEX junking systems is getting a precedence for responsible drivers.

Oil painting and Gas Compliance Trends Driving New Equipment Precedences

Compliance across oil painting and gas sectors is getting decreasingly complex. Regulations are no longer limited to emigrations; they now cover constraint, waste running, safety protocols, and broader impacts on ecosystems. This shift has accelerated demand for environmentally aligned outfit like the jatco shell and tube systems and the compact 10 gallon environmental tank. Operations are now needed to borrow pollution control outfit for oil painting and gas installations, enabling effective running of hydrocarbons, vapors, and defiled fluids. As businesses seek to remain competitive and avoid compliance penalties, jatco environmental tanks and other technical constraint systems play a pivotal part in satisfying legal prospects, precluding tumbles, and securing natural coffers. The focus is now on erecting systems that can repel changeable functional challenges while proactively addressing nonsupervisory scores.

Sustainability as a Strategic Advantage in oil painting and Gas

As global diligence shift toward greener practices, the oil painting and gas sector is under mounting pressure to borrow technologies that promote long- term sustainability. The use of systems like the jatco shell and tube heat exchanger paired with a 10 gallon environmental tank helps drivers lower emigrations, reduce thermal waste, and better control pollutants. These technologies integrate easily with strategies meant to heighten environmental sustainability in oil painting and gas assiduity operations. Environmental systems similar as jatco tanks, especially when used along with a btex eliminator system, give an added subcaste of environmental protection by efficiently managing dangerous derivations. Through bettered constraint, better filtration, and advanced heat exchange capabilities, companies can reduce their environmental footmark and strengthen their position as leaders in sustainable energy operation.

Integrated Systems for Effective Pollution Control

The elaboration of pollution control outfit for oil painting and gas has redounded in advanced systems able of addressing complex derivate aqueducts and chemical relations. Platforms integrating the jatco shell and tube approach into their structure frequently profit from bettered molecular separation and thermal effectiveness. When paired with a 10 gallon environmental tank, installations achieve further streamlined separation processes and optimized derivate running. The use of jatco environmental tanks extends these advantages by icing accoutrements remain safely contained and ready for regulated disposal or recycling. This approach directly supports measures to reduce emigrations, ameliorate air and water quality, and foster functional models aligned with long- term environmental protection. The precedence moment is to emplace integrated systems that are reliable, easy to maintain, and able of spanning with evolving nonsupervisory fabrics.

Improving installation Workflow Through Smarter Tank and Exchanger Pairings

One of the crucial benefits of pairing a jatco shell and tube exchanger with a 10 gallon environmental tank is the improvement of fluid inflow and thermal stability in diurnal operations. These systems allow installations to simplify workflows, reduce time-out, and ameliorate safety during high- affair cycles. The integration of constraint systems like jatco tanks results in better control over dangerous and nonhazardous fluids, minimizing pitfalls and supporting environmental compliance for oil painting and gas. also, by incorporating the btex eliminator system, installations can more manage airborne pollutants and meet air- quality conditions. The result is a more effective, safer plant where outfit life and nonsupervisory compliance go hand in hand.

Tailored Environmental results for Unique Site Demands

Oil painting and gas operations vary extensively, from compact drilling pads to large- scale refining complexes. This diversity demands customizable outfit able of meeting point-specific challenges. The jatco shell and tube exchanger is constantly acclimated for colorful functional sizes and thermal conditions, while the 10 gallon environmental tank remains ideal for constraint in lower zones or technical processes. The vacuity of flexible configurations in jatco environmental tanks allows installations to acclimatize to original nonsupervisory guidelines, terrain limitations, and chemical- running conditions. Adding factors like a btex eliminator system strengthens a installation’s capability to demonstrate a commitment to environmental sustainability in oil painting and gas assiduity stylish practices. These customized approaches give functional stability and insure that environmental pitfalls remain well- managed.

The Growing Need for High- effectiveness outfit in Future Energy geographies

The future of oil painting and gas revolves around smart, effective, and environmentally responsible technology choices. outfit like the jatco shell and tube exchanger and the 10 gallon environmental tank reflect the assiduity’s shift towards integrated environmental operation. With adding attention on pollution control outfit for oil painting and gas, installations are investing in high- performance results able of delivering clean, safe, and biddable operations. The strategic use of jatco tanks, coupled with advanced systems like the btex eliminator system, strengthens the foundation demanded to remain competitive in a fleetly evolving nonsupervisory terrain. These technologies not only insure compliance but also lay the root for unborn sustainability- driven inventions across the sector.

Conclusion

In an assiduity that demands trustability, environmental responsibility, and high- performance outfit, the integration of systems similar as the jatco shell and tube exchanger and the 10 gallon environmental tank remains essential. Their combined strength in thermal regulation, constraint, and environmental protection makes them necessary for drivers facing adding nonsupervisory and sustainability challenges. When supported by advanced results like jatco environmental tanks, jatco tanks, and the btex eliminator system, companies gain the tools they need to exceed in both functional effectiveness and responsible resource operation. As the energy request evolves, technologies that support environmental compliance for oil painting and gas and support pollution control outfit for oil painting and gas will continue shaping the future of the sector. For associations seeking reliable, innovative, and environmentally aligned results, Jatco Inc remains a trusted assiduity leader.

FAQs

What’s the main purpose of a shell and tube heat exchanger in oil painting and gas?

It regulates temperature within process systems, icing stable operations and precluding overheating or thermal inefficiencies.

Why is environmental compliance adding significance for oil painting and gas companies?

Regulatory agencies are administering strict rules to cover air, water, and land coffers. Companies must misbehave to avoid penalties and maintain safe operations.

What does a BTEX eliminator system help remove?

It helps exclude benzene, toluene, ethylbenzene, and xylene from vapor aqueducts, perfecting safety and air quality.

Why are environmental tanks essential in oilfield operations?

They insure safe constraint of fluids and derivations, reducing slip pitfalls and supporting safe disposal or recycling practices.

Are compact tanks like a 10 gallon environmental tank useful?

Yes, they’re ideal for operations with space limitations or technical constraint needs within lower processing units.