Discover How a Lab-Scale Hydrothermal Autoclave Enhances Synthesis Efficiency – In the evolving world of materials science, nanotechnology, and chemical research, precise control over synthesis conditions is critical. One of the most effective tools to achieve this is the lab-scale hydrothermal autoclave. These compact, high-performance reactors have become indispensable in laboratories and research institutions around the world, thanks to their ability to facilitate high-purity, uniform material synthesis under controlled temperature and pressure environments.

lemari asam explores how a lab-scale hydrothermal autoclave enhances synthesis efficiency, improves reproducibility, and supports the advancement of experimental research.

What Is a Lab-Scale Hydrothermal Autoclave?

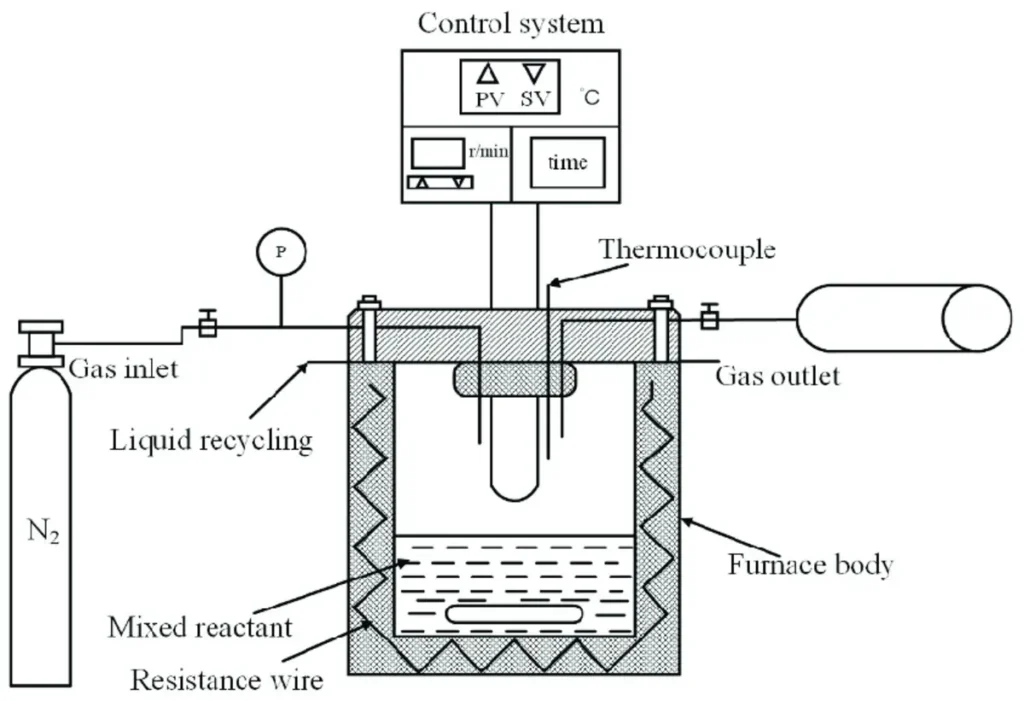

A lab-scale hydrothermal autoclave is a small-capacity, high-pressure reactor designed for synthesizing advanced materials through hydrothermal reactions. The core function of this device is to contain solutions under high temperature and pressure, typically above the boiling point of water, to promote the formation of crystalline compounds and nanoparticles.

Most units feature a Teflon-lined stainless steel chamber, which ensures chemical resistance and thermal stability, making them ideal for handling corrosive or reactive materials. With customizable volumes ranging from 25 mL to 500 mL, lab-scale autoclaves are suited for research applications that require high precision and reproducibility in small batches.

Advantages of Using a Lab-Scale Hydrothermal Autoclave

1. Enhanced Reaction Control

One of the primary benefits of a lab-scale autoclave is the precise control it offers over reaction parameters. Researchers can fine-tune temperature, pressure, and time to optimize synthesis conditions. This level of control enables:

– Better yield of desired phases or structures.

– Formation of uniform particle sizes.

– High crystallinity of products.

For materials like metal-organic frameworks (MOFs), zeolites, or metal oxide nanoparticles, this control is crucial to achieving desired functional properties.

2. Improved Efficiency and Speed

Hydrothermal synthesis often results in faster reaction kinetics compared to ambient methods. The sealed environment of an autoclave accelerates reactions and promotes the formation of high-purity products in less time. This means:

– Shorter experimental timelines.

– Higher throughput in laboratory settings.

– Reduced reagent consumption.

3. Reproducibility and Consistency

In research, reproducibility is everything. Lab-scale hydrothermal autoclaves help minimize batch-to-batch variations through uniform heating and reliable sealing mechanisms. Many models now include digital temperature controllers and integrated safety features that ensure consistent outcomes, making them a trusted choice for institutions focused on experimental integrity.

Applications in Research and Industry

Lab-scale hydrothermal autoclaves are widely used across various scientific disciplines:

Nanomaterials Synthesis: From quantum dots to nanorods, autoclaves are essential for controlling morphology and crystal growth.

Catalyst Development: Creating high-surface-area catalysts with specific active sites requires uniform conditions achievable via hydrothermal techniques.

Energy Materials: Autoclaves are used to fabricate battery electrode materials, fuel cell components, and supercapacitor substances.

Environmental Studies: Researchers use hydrothermal synthesis to develop sorbents and photocatalysts for pollutant removal.

These applications demonstrate the broad utility of lab-scale autoclaves beyond traditional chemistry, making them a cornerstone in interdisciplinary research.

Choosing the Right Lab-Scale Hydrothermal Autoclave

When selecting an autoclave for laboratory use, institutions should consider several factors:

Volume and Capacity: Choose a size based on your throughput needs. For single-batch experimental trials, 50–100 mL is typically sufficient.

Temperature and Pressure Range: Most units operate safely up to 250°C and 3 MPa, but higher-performance models can exceed this.

Material Construction: Stainless steel with a PTFE liner offers both strength and chemical resistance.

Ease of Use and Safety: Look for features like pressure release valves, thermal fuses, and digital displays for user-friendly and secure operation.

Manufacturers also offer custom lab-scale autoclave systems with stirring, multiple chambers, or advanced sensors to meet specific research requirements.

Maintenance and Safety Best Practices

To ensure longevity and safe operation:

– Always inspect the gasket and Teflon liner for wear before use.

– Avoid overfilling to prevent excessive pressure buildup.

– Use only with approved chemicals compatible with PTFE and stainless steel.

– Follow manufacturer cleaning protocols to avoid cross-contamination.

Proper use and maintenance not only extend the life of the autoclave but also safeguard the accuracy and reliability of your research.

Final Thoughts

For laboratories and institutions aiming to elevate their material synthesis capabilities, a lab-scale hydrothermal autoclave is an investment in precision, efficiency, and innovation. Whether you’re developing new nanomaterials or testing environmental solutions, this powerful tool provides the control and consistency that modern research demands.

Integrating a lab-scale autoclave into your workflow can streamline experimental processes, enhance reproducibility, and ultimately accelerate discovery. As science pushes the boundaries of the microscopic world, having the right equipment can make all the difference.