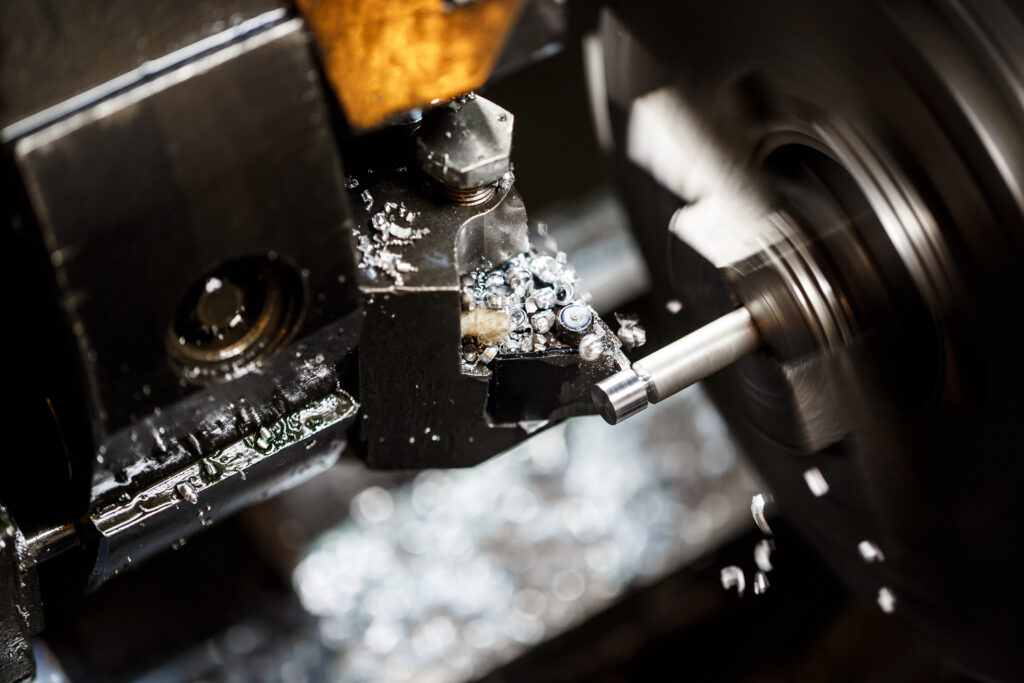

Close up photo of metalworking machine on plant.

In the world of contemporary production, precision and reliability are non-negotiable—specially in terms of producing additives for crucial industries together with aerospace, medical, telecommunications, and protection. Among the many advanced machining strategies available, CNC Swiss machining stands out for its potential to deliver extremely-specific, high-tolerance components at scale. From tiny additives in surgical devices to custom fasteners for aerospace structures, Swiss machining has emerge as the cornerstone of fastener specialties manufacturing and plenty of different excessive-call for sectors.

What Is CNC Swiss Machining?

CNC Swiss machining, firstly advanced for the Swiss watch enterprise, refers to a particular sort of precision turning that allows for extraordinarily tight tolerances and difficult detailing. A key feature of Swiss-kind lathes is that the bar inventory actions through a manual bushing, which helps the material very near the cutting device. This layout substantially reduces deflection and vibration, taking into consideration greater strong and correct machining—even on very narrow or complex parts.

In evaluation to standard CNC lathes, which preserve the workpiece stationary at the same time as the cutting equipment circulate, Swiss machines move the material itself. This allows simultaneous operation on a couple of axes and high-velocity manufacturing of elements with complex geometries and nice finishes.

The Key Advantages of CNC Swiss Machining

1. Unparalleled Precision for Tight Tolerances

One of the main motives manufacturers turn to CNC Swiss machining is its capability to hold noticeably tight tolerances—often within ±zero.0002 inches or even tighter, relying on the material and layout. This level of accuracy is vital in industries wherein even microscopic deviations can reason issue failure or meeting problems.

This is mainly essential in fastener specialties production, wherein the reliability of threaded or grooved components directly impacts the safety and functionality of an quit product. Whether you’re producing aerospace-grade screws or custom medical implants, Swiss machining guarantees repeatable precision at each step.

2. Exceptional Surface Finish Quality

Surface end is another place wherein Swiss machining excels. With less vibration and better manage over the fabric’s role throughout reducing, CNC Swiss machines can produce parts with smoother finishes—regularly decreasing or casting off the need for secondary sprucing or completing procedures.

This translates to price savings, advanced aspect overall performance, and better product aesthetics, especially critical for consumer-going through packages or components that require fluid dynamics considerations, which includes nozzles or surgical equipment.

Three. Efficient Production of Complex Geometries

Swiss-type machines are regarded for his or her ability to deal with complex, multi-featured parts in a unmarried setup. With tools located on more than one axes and capable of simultaneous machining, complicated operations like go-drilling, milling, threading, knurling, and grooving can all be finished with out shifting the element to every other machine.

This is in particular high-quality for fastener specialties production, in which a few custom fasteners can also require hexagonal heads, specific undercuts, or multi-threaded shafts. CNC Swiss machining can manage these challenges comfortably, resulting in fewer setups, decreased cycle instances, and higher basic efficiency.

Four. Minimal Material Waste and Optimized Cycle Times

Because of the green cloth feed and specific slicing abilties, CNC Swiss machines significantly reduce cloth waste. The close tolerance capability manner fewer parts are scrapped because of dimensional errors. Additionally, Swiss machines are optimized for excessive-velocity, lights-out manufacturing—wherein machines run unattended for prolonged periods—making them best for excessive-quantity runs.

This degree of productivity is vital in industries like aerospace and car, wherein element demand is excessive and closing dates are tight. Reduced cloth consumption additionally aligns with current sustainability desires through minimizing scrap and reducing the carbon footprint of production tactics.

Five. Ideal for Small Diameter and Long Parts

Unlike conventional lathes, CNC Swiss machines are designed particularly to excel in machining lengthy, slender parts without compromising balance. This is made viable through the guide bushing mechanism, which helps the workpiece close to the slicing location.

Whether you’re generating thin clinical guide wires or long threaded fasteners, the Swiss method ensures straightness, consistency, and first-rate first-rate at some point of the entire period of the element.

6. Scalability from Prototype to Production

Another major gain of CNC Swiss machining is its scalability. The same gadget that creates prototypes with tight tolerances can without difficulty scale up to complete manufacturing runs. This makes it an outstanding choice for businesses trying to pass fast from layout to marketplace without sacrificing best or consistency.

For fastener specialties production, this functionality is valuable. Whether pleasing a small batch for R&D or meeting excessive-volume orders for an OEM, Swiss machining permits seamless transitions with minimal downtime or tooling adjustments.

7. Supports a Wide Range of Materials

CNC Swiss machining is well suited with a large array of substances, together with stainless steel, titanium, brass, aluminum, and excessive-overall performance plastics like PEEK and Delrin. This versatility lets in manufacturers to supply components ideal for extreme environments—whether meaning high heat, corrosive chemical compounds, or heavy masses.

In the fastener world, material integrity is paramount. Swiss machining offers the power to work with uniqueness alloys and substances regularly required for aerospace fasteners, clinical implants, or custom commercial components.

Real-World Application: Fastener Specialties Manufacturing

Fastener specialties manufacturing is a discipline where tolerances, fabric strength, and custom capabilities can mean the difference among performance and failure. Whether generating a high-load structural bolt for plane meeting or a corrosion-resistant fastener for marine programs, Swiss machining affords the control and precision to meet stringent requirements.

At organizations like Allied Technologies, CNC Swiss machining plays a significant function in handing over custom fasteners that meet AS9100D, ISO 13485, and other industry certifications. Each fastener isn’t handiest machined to precise specifications but is also established via rigorous satisfactory manipulate techniques.

Fastener experts depend upon Swiss machining now not only for its precision, but for the consistency it offers across thousands—or maybe thousands and thousands—of elements. This reliability is vital while additives should perform underneath extreme conditions and can not manage to pay for to fail.

Conclusion: The Future of High-Tolerance Machining

CNC Swiss machining has converted the manner high-precision parts are synthetic. Its capability to deliver tight tolerances, complicated capabilities, and efficient manufacturing cycles has made it crucial across industries like aerospace, clinical, telecom, and beyond.

As the demand for miniature, complex, and dependable additives maintains to grow, CNC Swiss machining will continue to be at the vanguard of innovation and efficiency. For agencies concerned in fastener specialties manufacturing, embracing Swiss technology is more than an operational choice—it is a strategic benefit in turning in top-tier best and performance.

Whether you are scaling up manufacturing, optimizing for precision, or pushing the limits of thing layout, CNC Swiss machining is your associate in building the destiny—one excessive-tolerance element at a time.