Automated Riveting Machine

In today’s competitive manufacturing environment, precision, efficiency, and scalability are key to success. One of the most effective ways to boost these qualities in your production line is through Automated Riveting Machine integration. These machines can streamline the riveting process, ensuring consistent quality, faster throughput, and reduced labor costs.

But what exactly is an automated riveting machine, and how does it fit into your manufacturing operations? In this article, we’ll dive into the benefits, types, and key considerations for integrating automated riveting machines into your production lines. Whether you’re in aerospace, automotive, or electronics, these machines are built to enhance your operations.

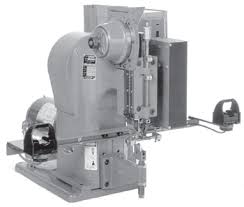

What Is an Automated Riveting Machine?

An automated riveting machine is a specialized piece of equipment used in manufacturing to install rivets automatically. Riveting, a common joining process in industries such as automotive and aerospace, involves fastening two or more materials together with a metal pin or rivet. Automated riveting machines eliminate manual labor by using robotic arms, sensors, and other automated technology to precisely position and fasten rivets.

The primary advantage of these machines is their ability to perform this repetitive task with high speed and consistency. This reduces errors, ensures better product quality, and increases the overall efficiency of the production line.

Benefits of Integrating an Automated Riveting Machine

Integrating an automated riveting machine into your production line offers several key benefits:

-

Enhanced Precision: These machines are programmed to install rivets with exact positioning and force, reducing human error and ensuring consistent quality.

-

Increased Efficiency: Automation speeds up the riveting process, allowing manufacturers to complete more tasks in less time.

-

Cost Reduction: By automating the process, businesses can reduce labor costs, minimize waste, and improve overall operational efficiency.

-

Improved Safety: Automated machines reduce the risk of workplace injuries associated with manual riveting, as workers aren’t exposed to repetitive strain.

-

Scalability: As your production needs grow, an automated riveting system can be scaled to accommodate higher volumes without sacrificing quality.

Different Types of Automated Riveting Machines

There are several types of automated riveting machines, each designed to meet the specific needs of different industries and production processes. Some common types include:

1. Pneumatic Riveting Machines

These machines use compressed air to drive the rivet into place. They are ideal for high-speed applications where force is needed to join materials efficiently.

2. Electric Riveting Machines

Using electric motors, these machines provide precise control over the riveting process, offering greater energy efficiency and reducing maintenance costs.

3. Servo-Driven Riveting Machines

Servo-driven machines offer high precision and can be programmed to operate at various speeds. This makes them suitable for complex applications where accuracy is critical.

4. Robotic Riveting Systems

These systems are integrated with robotic arms, making them highly flexible and capable of handling intricate riveting tasks. They are particularly beneficial in industries that require complex parts assembly, such as aerospace.

How Automated Riveting Machines Fit into Your Manufacturing Workflow

Automated riveting machines can seamlessly integrate into existing production lines. Here’s how:

1. Assessment and Customization

Automation experts assess your current production line to identify areas that can benefit from riveting automation. They will then design a custom solution that fits seamlessly with your existing machinery.

2. System Integration

Automated riveting machines are integrated with your production line, ensuring that the flow of materials, parts, and rivets is synchronized with the rest of your manufacturing process.

3. Automation of Supporting Processes

In addition to riveting, automation experts can also integrate related processes such as feeding, inspection, and quality control, creating a fully automated solution that maximizes efficiency.

Key Considerations for Integrating an Automated Riveting Machine

While automated riveting machines can offer significant benefits, it’s important to consider a few factors before integration:

1. Production Volume and Speed

Automation is most beneficial when dealing with high-volume production. If your production line operates at lower volumes, a manual riveting process might still be more cost-effective.

2. Compatibility with Existing Systems

Ensure that the automated riveting machine is compatible with your current machinery and production systems. Integration experts can help design a solution that works smoothly within your existing setup.

3. Maintenance and Support

Like any automated system, regular maintenance is essential for long-term performance. Be sure to choose a solution provider that offers reliable support and service to ensure continuous operation.

The Role of Automation Experts in Riveting Machine Integration

Successfully integrating an automated riveting machine into your production line requires expert knowledge and experience. Automation experts can guide you through every step of the process, from initial assessment to installation and ongoing maintenance.

These experts will:

-

Design a tailored solution that aligns with your specific needs and goals.

-

Ensure seamless integration with your current systems.

-

Train your team on how to operate and maintain the new system.

-

Provide continuous support and troubleshooting to minimize downtime.

Automation vs. Manual Riveting: A Comparison

For many manufacturers, the decision to move from manual riveting to automation is a big one. Here’s a quick comparison:

-

Speed: Automated riveting machines work faster than manual processes, allowing for higher production rates.

-

Quality Control: Automated systems ensure consistent rivet placement and quality, while manual riveting is prone to human error.

-

Labor Costs: Automation reduces the need for manual labor, cutting labor costs in the long run.

-

Flexibility: Manual riveting allows for more flexibility in terms of part sizes, while automated machines are designed for high precision and speed.

Ultimately, the choice between manual and automated riveting depends on your production requirements and long-term goals.

Cost of Implementing Automated Riveting Machines

While the upfront cost of automated riveting machines can be significant, the long-term savings and productivity gains typically make the investment worthwhile. The cost will depend on several factors, including:

-

The type of automated riveting machine (pneumatic, electric, robotic, etc.)

-

The level of customization required for your production line

-

Installation and integration costs

-

Ongoing maintenance and support

For many businesses, the cost savings from reduced labor and improved efficiency offset the initial investment, making automation a sound financial decision.

Future of Automated Riveting Machines

The future of automated riveting is closely tied to advancements in robotics, AI, and machine learning. Upcoming trends include:

-

AI Integration: Artificial intelligence can be used to optimize riveting processes and ensure real-time quality control.

-

Increased Flexibility: New systems are being developed to handle a wider range of materials and part sizes, providing even more versatility in manufacturing.

-

Sustainability: Automated riveting systems will likely become more energy-efficient and environmentally friendly, reducing waste and energy consumption.

By embracing these innovations, manufacturers can further optimize their production lines and stay ahead of the competition.

Final Thoughts

Automated riveting machine integration offers a powerful solution for manufacturers looking to enhance productivity, precision, and efficiency. By investing in automated systems, businesses can reduce labor costs, improve product quality, and scale their operations with ease. With the right integration strategy and support, automated riveting machines can become an essential part of your manufacturing success.