Laser engraving has revolutionized the world of customization, artistry, and industrial manufacturing. Whether it’s crafting detailed artwork, personalizing gifts, or marking industrial components, a laser engraver offers exceptional precision and versatility. With growing demand across various industries, businesses and hobbyists alike are investing in this advanced engraving technology.

Understanding How a Laser Engraver Works

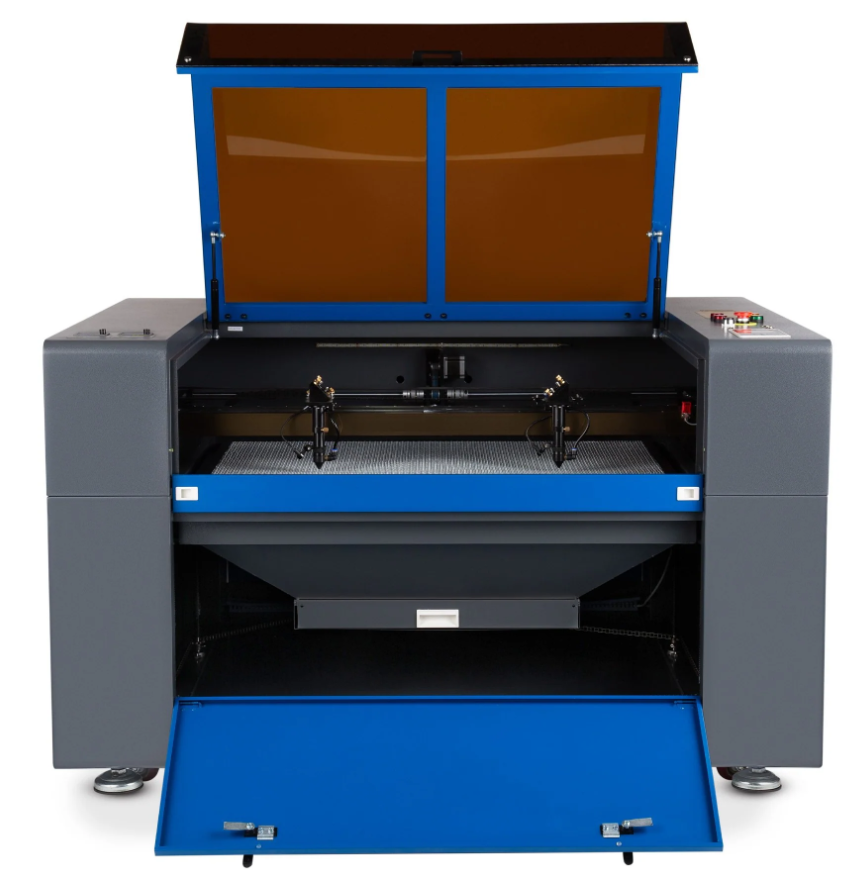

A laser engraver operates by directing a focused laser beam onto a material’s surface, altering its texture or removing layers to create precise engravings. The process involves high-intensity light interacting with the material to produce permanent, intricate designs without physical contact.

Different types of laser engravers use varying technologies, including CO2, fiber, and diode lasers, each suitable for specific materials. While CO2 lasers work well on wood, acrylic, and glass, fiber lasers are preferred for engraving metals. Diode lasers, on the other hand, are often used for marking softer materials.

Materials Compatible with Laser Engraving

A laser engraver is widely used across multiple industries due to its compatibility with a variety of materials. Some of the most common materials include:

-

Wood – Used in creating artistic designs, customized wooden plaques, and furniture embellishments.

-

Metal – Ideal for industrial applications, jewelry engraving, and branding.

-

Glass – Commonly used for decorative pieces, awards, and drinkware.

-

Leather – Engraved for personalized wallets, belts, and accessories.

-

Acrylic & Plastics – Often used in signage, keychains, and display stands.

-

Paper & Cardboard – Applied in customized invitations and packaging solutions.

The precision of a laser engraver ensures that even the most intricate details are visible on these materials, making it a preferred choice for both commercial and personal projects.

Applications of Laser Engraving

The use of a laser engraver extends beyond simple etching. Various industries benefit from its capabilities, including:

1. Personalized Gifts and Customization

Laser-engraved gifts are a growing trend. Engraving names, quotes, or designs on items like phone cases, jewelry, and home décor adds a unique touch that appeals to customers looking for one-of-a-kind products.

2. Industrial Marking and Branding

Manufacturers use laser engravers to mark serial numbers, barcodes, and logos on machinery and tools. The permanence of laser-engraved markings ensures durability and authenticity.

3. Art and Craft Industry

Artists and designers leverage laser technology to create intricate patterns and textures on a range of materials. Whether for decorative wall panels or custom artwork, a laser engraver enables high-precision detailing.

4. Signage and Advertising

Businesses use laser engraving for creating high-quality signs, nameplates, and promotional items. The technology ensures a professional, polished look, making branding materials stand out.

5. Jewelry Engraving

From wedding bands to luxury watches, laser engraving adds precision and uniqueness to jewelry. The process ensures detailed, fine-line engraving without damaging delicate pieces.

6. Automotive and Aerospace Industry

A laser engraver is essential for engraving identification numbers, serial codes, and safety instructions on car parts and aircraft components. The engraved markings withstand extreme conditions, ensuring long-term traceability.

7. Medical Equipment Engraving

Medical tools and devices require clear, permanent markings for identification and compliance with industry regulations. Laser engraving provides a non-toxic, wear-resistant solution for marking medical instruments.

Choosing the Right Laser Engraver

Selecting the right laser engraver depends on factors such as material type, engraving depth, and industry requirements. Key considerations when purchasing include:

-

Laser Type – CO2, fiber, or diode lasers have different capabilities and applications.

-

Power & Speed – Higher wattage allows for deeper engraving and faster production.

-

Software Compatibility – User-friendly software enhances design flexibility and ease of operation.

-

Work Area Size – The engraving bed size determines the maximum material dimensions that can be processed.

-

Cooling System – Some machines require cooling mechanisms to prevent overheating.

Investing in a quality laser engraver ensures efficiency, accuracy, and long-term productivity, making it a valuable asset for businesses and professionals.

Maintenance and Care for a Laser Engraver

To ensure optimal performance and longevity of a laser engraver, regular maintenance is crucial. Some essential care tips include:

-

Cleaning the Lens and Mirrors – Dust and debris can affect laser precision. Regular cleaning enhances output quality.

-

Checking Alignment – Misaligned mirrors impact laser focus. Adjustments maintain engraving accuracy.

-

Proper Ventilation – Ensuring adequate airflow prevents overheating and prolongs machine life.

-

Routine Software Updates – Keeping engraving software updated enhances functionality and performance.

-

Material-Specific Settings – Using appropriate power and speed settings for different materials prevents damage.

A well-maintained laser engraver ensures consistent, high-quality results and reduces the chances of costly repairs.

Future of Laser Engraving

As technology advances, laser engravers continue to evolve with enhanced speed, accuracy, and automation. Industries are incorporating artificial intelligence and smart software for more precise control and increased efficiency. The demand for personalized products, intricate designs, and durable markings will continue to drive the growth of laser engraving applications across various sectors.

Final Thoughts

A laser engraver is an indispensable tool for businesses, artists, and manufacturers looking for precision and durability in engraving applications. From custom gifts to industrial marking, its versatility and efficiency make it a valuable investment. By selecting the right machine, maintaining it properly, and leveraging its full potential, users can unlock endless creative and commercial possibilities.

Whether you’re an entrepreneur aiming to expand your product line or a professional seeking accuracy in industrial marking, a laser engraver offers unmatched precision and reliability for a wide range of applications.