Are you working in the automotive, precision engineering and heavy machinery sectors? Would you like to buy the outstanding gear-shaping cutter tool? The below guide is for you. You can easily understand the gear shaping cutter and manufacturers by reading the entire topics given below. In gear manufacturing corporations, there is a necessity for shaping instruments that recreate a vital part. It enables employees to tailor the tools to their specific needs.

You can purchase the required type of gear shaper cutter, considering both its quality and cost. Upon taking a glance at this comprehensive guide, you can gather valuable knowledge about the manufacturers and the gear shaping cutter tool. Continue reading the content below to gather more information quickly.

Understand about gear shaping cutter and its types:

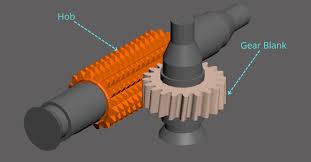

It is essential to know about the gear shaper cutter types and the cutter before buying it from the best manufacturers. A gear shaper cutter tool promotes the shaping of gear teeth via a straightforward approach. Gear shaping employs a reciprocating gesture to cut interior and exterior gears with elevated exactness and a soft texture impression. The key types of gear-shaping cutters include disk-type cutters, hub-type cutters, shank-type cutters and serration or spline cutters.

Benefits of using gear shaper cutting tools in industries:

You should understand the benefits of using the gear shaper-cutting tool in various enterprises. The benefits of utilizing the gear shaper engraving device in multiple sectors include its high accuracy in gear shapes, the ability to cut both inner and outer bags, its usefulness for complex and periodic gear shapes, and its cost-effectiveness for medium to large batch production. It is also efficient for material removal, offers a consistent surface finish, and is automation-friendly and CNC-compatible, making it versatile across various materials. The above-listed are the great benefits of using the gear shaper cutting tool in multiple industries.

Reasons for selecting Indian manufacturers:

Buying gear shaping cutters is a tedious task that takes more time. If you choose the gear shaper cutter manufacturers in india, it would be an easier way for you to save money. Here are the compelling reasons to choose Indian shaper cutter manufacturers for your business needs. It is due to cost-effective production, export-grade quality, customization, and engineering expertise. These are the key reasons for selecting Indian manufacturers to purchase gear shaper cutters for your large industry.

Specialties to recognize while purchasing gear shaper cutter:

When selecting the most suitable grade gear shaper cutter, it is essential to evaluate every part. There are additional elements to consider when purchasing gear shaping cutters tailored to your expectations and requirements. Key elements to consider include module length, force angle compatibility, fabric, and layer for durability, tooth profile precision, lead period, after-sales support, tool energy, and point options. Here are the fundamental specialties to recognize when buying gear shaper cutters.

Conclusion:

Therefore, the data furnished above allows you to understand everything regarding gear shaper manufacturers and gear shaper cutter tools. When you are ready to buy, please refer to this guide for more valuable details.