fastener specialties manufacturing

Most people don’t care about screws. Seriously, they don’t. But for engineers, one tiny fastener can make or break a project. That’s where fastener specialties manufacturing comes in. These aren’t your off-the-shelf screws from the hardware store. We’re talking precision stuff, designed to perform every single time. And the truth? Quality and reliability aren’t accidents. They’re built in from the start, every single step.

Materials Matter More Than You Think

It starts with the metal. You can’t make a high-grade bolt from junk steel and expect miracles. Top manufacturers spend a ton of time picking materials that meet strict specs. Tensile strength, corrosion resistance, chemical composition—it’s all checked. And yeah, tiny impurities can ruin a batch. So, they don’t just guess. Materials are tested, retested, and sometimes tested again.

Design That Actually Works

Design is not optional. Engineers run simulations, check tolerances, and stress-test the software before anything gets cut. It’s a bit overkill, maybe, but necessary. A poorly designed fastener fails no matter how good the machining is. And in fastener specialties manufacturing, failure is not allowed. End of story.

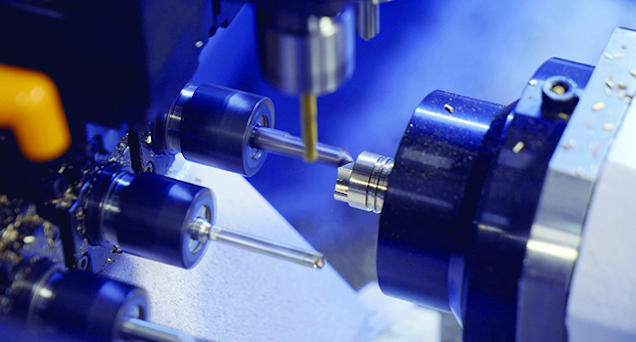

Swiss Machining for Tiny Details

Swiss machining is where the magic happens. These machines are insane—threading, micro-tolerances, tiny geometries you can’t even see with your eyes. The point isn’t just to make a part fast. It’s repeatability. Every screw, every batch, same exact specs. Skip this, and you might as well be playing roulette with your parts.

Quality Control Everywhere, Not Just at the End

Some people think QC is one final check. Nope. It’s everywhere. Materials, in-process inspections, torque tests, and visual checks. Some places even use cameras to catch stuff humans would miss. By the time a fastener leaves the floor, it’s been poked, prodded, tested, and probably insulted a few times. Reliability isn’t hoped for. It’s proven.

Heat Treatment and Finishing

Here’s a thing that surprises people: heat treatment and surface coating aren’t just fancy add-ons. They make fasteners stronger, harder, and corrosion-resistant. Do them wrong, and you’ve got a pretty piece of metal that fails on day one. Top manufacturers calibrate ovens, measure coatings, and check threads. It’s boring, tedious, but it works.

Traceability Isn’t Paperwork, It’s Life

Certificates, serial numbers, heat lot info—they’re not just bureaucratic nonsense. Traceability lets engineers track back problems to the source. Aerospace, medical devices… one mistake and it’s a disaster. That’s why every batch is documented, logged, often in excruciating detail. Sounds tedious, but trust me, it saves lives.

Field Testing Beats Lab Testing

Labs are fine, but real-world testing? That’s the proof. Fasteners get put through high loads, vibration, extreme temps, chemicals—you name it. Manufacturers monitor, tweak, and adjust. Sometimes it’s messy, sometimes frustrating. But nothing beats seeing your part survive the real deal. That’s how you know reliability isn’t just marketing hype.

Conclusion

So yeah, how do fastener specialties manufacturers make sure their stuff works? Materials, design, Swiss machining, QC everywhere, heat treatment, traceability, real-world testing… the whole package. Every step matters. Skip one, and the whole fastener could fail. And when that happens, everything else fails too. That obsession with details, the messiness, the constant testing—that’s what makes these fasteners trustworthy. You notice them only when they fail. And in this industry, noticing is way too late.