Precision investment casting

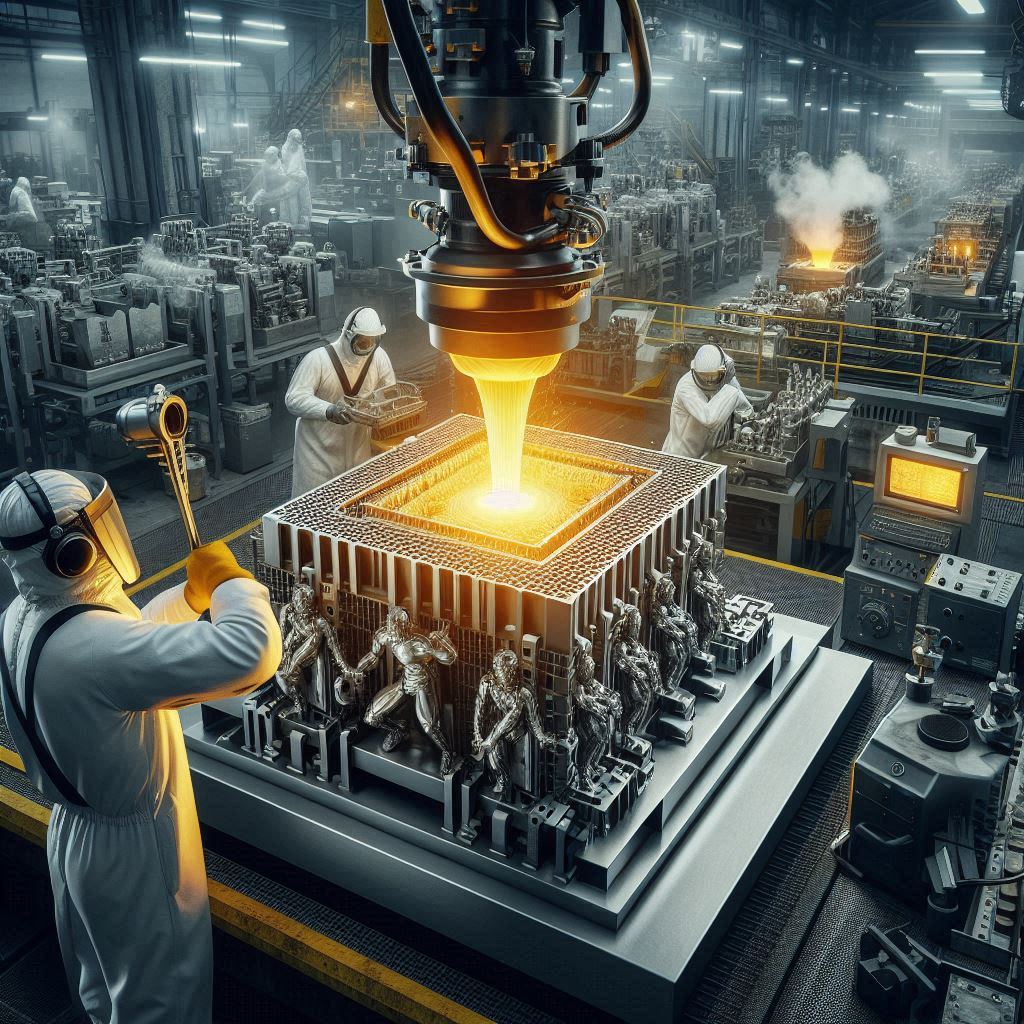

Precision investment casting or lost-wax casting is well esteemed for manufacturing intricate geometries, tighter tolerances, and superior finishes on components. The process begins by making a wax pattern which is called an investment pattern. It makes the final part. Once the investment pattern goes through the jacket of a ceramic slurry, it forms a shell, the hardened one after multiple applications. The shell being cured is melted away after the wax has cured, and the molten metal is poured into the cavity created therein. Once cool, the ceramic mold is stripped off, in a process that yields a casting very close to the final product, thus requiring minimal further machining. The variations of the investment casting process for precision machining are such that it works with both ferrous and nonferrous metals from high alloy stainless steel through aluminum and titanium. The ability to produce very complex shapes with extreme dimensional accuracy makes precision investment casting suitable for aerospace, automobile, medical, and industrial machinery application fields, with a high demand for high-performance and reliable components.

Advancements in Precision Investment Casting Technologies

It is this precision investment casting technology that will redefine the efficiency, accuracy, and versatility in the casting process. An Advancement of 3D-printing for disposable pattern-making falls under this category, making it possible to manufacture complex shapes without the requirement of regular tooling, thus shortening lead-time and costs. The development of super alloys has broadened investment casting applications, particularly those across aerospace and automotive industries, where components find themselves in extreme conditions. Furthermore, the adoption of all automation as well as digital control systems enhances the consistency of quality and process, enabling real-time monitoring and adjustments to the process during production. All this is leading to better use of resources with reduced waste and production of high-quality, complex components.

Comparing Precision Investment Casting with Other Casting Methods

Precision investment casting (also referred to as lost-wax casting) offers unique advantages over other casting methods such as sand casting and die casting. The outstanding advantage of this process is imbuing components with intricate geometry, thin walls, and very good surfaces, especially for applications where dimensional tolerance is a prime consideration. On the other hand, sand casting is better able to cater to larger, less-complex parts, as it renders a coarser finish and lower precision. Though die casting is very good for high-volume production and a good surface quality, it is generally limited to nonferrous metals and usually has high tool-making costs. Thus, thin-wall products of complex and high-precision criteria would often be considered for investment casting.