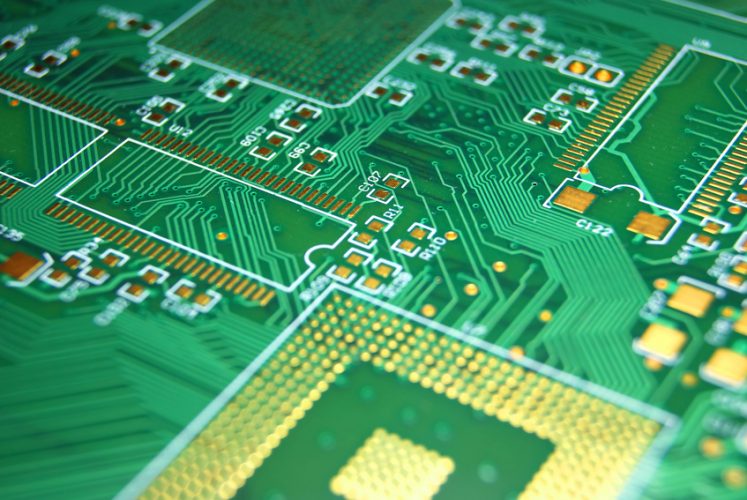

In the ever-evolving world of electronics, one of the most vital aspects driving innovation is PCB prototyping. Printed Circuit Boards (PCBs) are the backbone of nearly every electronic device, from smartphones to sophisticated medical devices. The process of prototyping these PCBs has undergone a revolutionary transformation, enabling faster development cycles, cost-effective solutions, and the ability to test designs more efficiently than ever before. This blog explores the PCB prototyping revolution, its impact on the electronics industry, and how it is reshaping the way new products are brought to life.

What is PCB Prototyping?

PCB prototyping is the process of creating a preliminary version of a PCB, often used to test its functionality before mass production. It allows engineers to verify a design, identify potential issues, and make necessary changes before committing to large-scale production. This iterative process is critical in electronics development, ensuring that designs are both functional and manufacturable.

The Traditional PCB Prototyping Challenges

Historically, PCB prototyping was a time-consuming and expensive process. Designers had to rely on long lead times, often waiting weeks for prototypes to be manufactured. This delay could result in missed deadlines and higher costs. Furthermore, the traditional prototyping process involved significant human labor, making the entire workflow inefficient and prone to errors.

With these challenges in mind, the demand for a faster, more affordable, and reliable approach to PCB prototyping has only grown. As electronics continue to advance, the need for rapid prototyping has become even more critical.

The Rise of Advanced PCB Prototyping Technologies

The rise of advanced PCB prototyping technologies has completely transformed the development cycle for electronic products. Today, companies are leveraging innovative solutions such as desktop PCB printers, automated manufacturing systems, and cloud-based design tools to streamline the prototyping process. These advancements have drastically reduced lead times, allowing for faster iterations and more refined designs.

Desktop PCB Printers

One of the most significant breakthroughs in PCB prototyping is the advent of desktop PCB printers. These compact and user-friendly machines allow engineers to design and manufacture PCBs in-house, eliminating the need for outsourcing to a third-party manufacturer. Desktop PCB printers make it possible to produce prototypes on-demand, reducing costs and lead times dramatically. Moreover, they offer the flexibility to test different variations of designs quickly, empowering engineers to refine their work in real-time.

Cloud-Based Design Tools

Another game-changing innovation is the rise of cloud-based design tools. These platforms enable engineers to collaborate on PCB designs from anywhere in the world. Real-time collaboration means that teams can work together seamlessly, resolving issues faster and improving the overall design process. Many of these tools also integrate simulation features, which allow engineers to test the functionality of their designs virtually before printing physical prototypes. This “virtual prototyping” can help identify flaws and optimize designs, reducing the need for multiple physical prototypes.

Automated Manufacturing Systems

Automated PCB manufacturing systems have also played a pivotal role in the PCB prototyping revolution. These systems allow for high-precision production with minimal human intervention. Automation not only speeds up the manufacturing process but also enhances the quality of the prototypes produced. The increased efficiency and consistency of automated systems have made it possible for companies to scale their operations while maintaining top-notch product quality.

Benefits of Rapid PCB Prototyping

The shift toward advanced PCB prototyping technologies has resulted in numerous benefits for engineers, designers, and companies involved in electronics development.

1. Speed to Market

One of the most significant advantages of rapid PCB prototyping is the reduction in lead times. With the ability to design and produce prototypes in-house or through automated systems, engineers can quickly test new ideas and make revisions without waiting weeks for external suppliers to deliver prototypes. This accelerated development process enables companies to bring their products to market faster, which is crucial in industries where time-to-market is a competitive advantage.

2. Cost Savings

By utilizing advanced PCB prototyping methods, companies can significantly reduce costs. Traditional PCB prototyping often involved expensive outsourcing to third-party manufacturers, which could lead to high production costs. Desktop PCB printers, for example, allow engineers to produce prototypes on-site, cutting down on outsourcing expenses. Moreover, the ability to test designs in the early stages reduces the likelihood of costly mistakes during mass production.

3. Design Flexibility

Rapid prototyping allows for greater flexibility during the design phase. Engineers can test different configurations and components quickly and make changes as needed. This iterative approach to design ensures that the final product is more refined and functional. PCB prototyping also enables designers to experiment with new materials and technologies, driving innovation in electronic device design.

4. Enhanced Testing and Validation

Testing is an integral part of the PCB prototyping process. With rapid prototyping capabilities, engineers can test their designs thoroughly before mass production begins. This testing phase helps identify potential flaws in the design, allowing for adjustments to be made before any significant investment is made in manufacturing. By catching errors early, companies can save time and money while improving the final product’s quality.

The Future of PCB Prototyping

As technology continues to advance, the future of PCB prototyping looks incredibly promising. Innovations such as 3D printing, artificial intelligence (AI)-driven design tools, and advanced material sciences will likely continue to improve the speed, quality, and cost-effectiveness of PCB prototypes.

For example, 3D printing may play a more significant role in the development of complex PCBs, enabling faster prototyping of intricate designs with unique geometries. AI-driven design tools could optimize the prototyping process even further, automating tasks such as error detection and design optimization.

Moreover, as consumer electronics continue to evolve, the demand for smaller, more powerful PCBs will drive advancements in PCB prototyping technologies. Engineers will need to design increasingly compact and efficient PCBs, which will require advanced prototyping techniques that can handle complex designs and materials.

Conclusion

The PCB prototyping revolution has significantly transformed the electronics industry. With faster turnaround times, reduced costs, and improved design flexibility, PCB prototyping is now more accessible than ever before. As new technologies continue to emerge, we can expect even more exciting developments that will further reshape the way electronic products are developed. To stay competitive in today’s fast-paced world of electronics, businesses must embrace these advancements and continue to innovate in their approach to PCB prototyping.

For those eager to dive deeper into this subject, check over here for additional insights into the latest in PCB prototyping technologies. Or, if you’re ready to take your project to the next level, click this link here now to explore the best solutions available for rapid prototyping. The future of electronics development is bright, and the possibilities are endless.