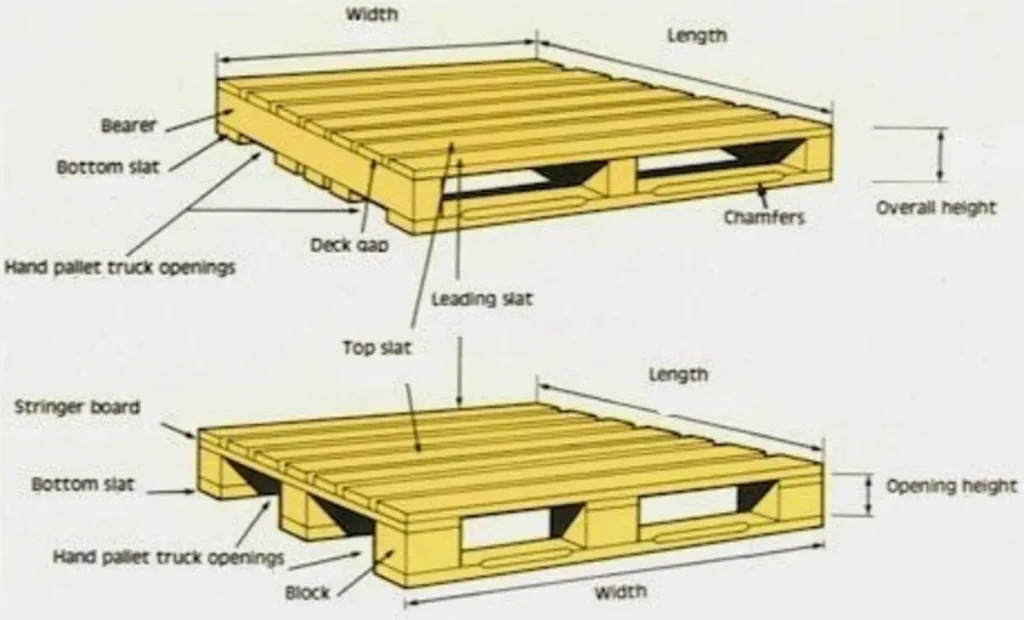

Wooden pallets play an essential role in global trade. They support the movement, storage, and protection of goods in nearly every supply chain. Their reliability makes them the backbone of warehouse operations, export logistics, and industrial production. Although simple in appearance, they are engineered with purpose. This article breaks down how Wooden Pallets work, where they excel, and why businesses continue to rely on them.

alternative material for interior/ exterior: pvc board – GSTARBOARD

What Wooden Pallets Do in Modern Logistics

Wooden Pallets provide a stable platform that allows forklifts, pallet jacks, and automated systems to lift and move products efficiently. Their core function is to make handling faster while reducing the physical strain and safety risks that come with loose stacking. Because they create uniform loads, they cut down the time needed to sort, pack, and transport goods.

They also serve as a protective buffer. Goods placed on pallets avoid direct contact with floors and moisture. This helps reduce contamination and damage. In storage environments, they improve airflow around products and support organized stacking. For companies that deal with bulk shipments, they are a practical tool for standardizing loads and keeping inventories more predictable.

Why Wooden Pallets Remain the Global Standard

There are several pallet materials available today, yet Wooden Pallets continue to dominate. Their widespread use is not driven by habit but by proven performance. They balance durability, cost efficiency, and adaptability better than any other option.

1. Strength and Load Capacity

Wooden Pallets handle heavy loads without losing structural integrity. Their high strength to weight ratio makes them suitable for dense or irregular products. This is why industries such as construction, manufacturing, chemicals, food processing, and agriculture consider them the most reliable solution.

2. Cost Effective for Large Operations

Affordability is a key reason companies select Wooden Pallets. They are less expensive to produce compared to plastic or metal pallets. When businesses need thousands of units, cost per pallet becomes critical. Wooden options offer strong value while maintaining performance.

3. Repairable and Long Lasting

One of the biggest advantages of Wooden Pallets is their repairability. If a deck board cracks or a block loosens, it can often be fixed at a low cost. This extends the working life of the pallet and reduces waste. Many pallets remain in circulation for several years through simple maintenance.

4. Customizable for Specific Needs

Companies with unique product dimensions can design Wooden Pallets that fit exactly. Custom sizing improves load stability and can reduce shipping costs by maximizing container and truck space. Custom builds also help protect fragile or high value goods.

Sustainability and Environmental Benefits

Contrary to expectations, Wooden Pallets are often more environmentally friendly than alternatives. They use renewable raw materials and maintain an efficient lifecycle.

1. Made From Renewable Resources

Wood comes from forests that many suppliers manage responsibly. This helps maintain long term sustainability while supporting local economies. Because wood is a natural material, it fits well within global goals for greener supply chains.

2. Recyclable and Reusable

At the end of their service life, Wooden Pallets do not become waste. They can be turned into mulch, particleboard, compost material, animal bedding, or fuel for biomass energy. This closed loop lifecycle minimizes environmental impact and supports circular economy practices.

3. Low Carbon Footprint

Producing Wooden Pallets typically requires less energy compared to manufacturing plastic or metal versions. Their long reuse cycle further reduces their overall footprint.

Compliance and Safety in International Shipping

Businesses shipping globally rely on pallets that meet international standards. The most important standard is ISPM 15. This rule helps prevent pests from crossing borders through untreated wood. Wooden Pallets that meet ISPM 15 requirements go through heat treatment or fumigation, making them safe for export.

Certified pallets are clearly stamped, which speeds up customs checks and avoids delays. Companies that work with reputable pallet manufacturers ensure their shipments stay compliant and move smoothly through international gateways.

Practical Tips for Using Wooden Pallets

To get the most out of Wooden Pallets, businesses should follow simple best practices.

Inspect regularly. Look for loose nails, cracked boards, or signs of moisture damage. Early repairs keep pallets strong.

Stack properly. When pallets are empty, stack them evenly to avoid warping. When loaded, keep weight centered.

Store in a dry area. Good ventilation reduces mold and maintains wood quality.

Choose pallets that fit your load. The right size improves safety and protects goods during transit.

Why Wooden Pallets Support a Better Supply Chain

Wooden Pallets bring together strength, versatility, sustainability, and cost control. They help create efficient workflows that support both small businesses and global enterprises. Their long record of reliability makes them a trusted partner in warehousing, transport, manufacturing, and export.

Whether a company needs standard sizes or custom designs, Wooden Pallets remain a smart investment. They simplify operations, protect products, and help build a leaner and more resilient supply chain.