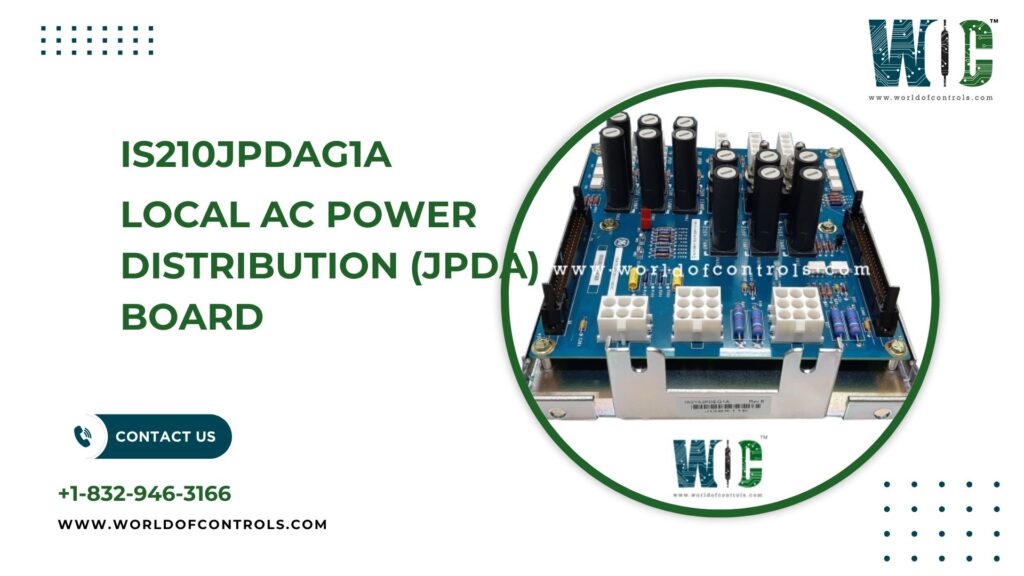

IS210JPDAG1A

In complex industrial systems such as gas and steam turbines, electrical reliability and safety are paramount. One of the critical components ensuring this reliability is the Local AC Power Distribution Board, often referred to in turbine applications as a JPDA (Junction Power Distribution Assembly). This board is essential for organizing, protecting, and delivering AC power to various subsystems within the turbine control environment.

Understanding Local AC Power Distribution

Local AC power distribution boards are responsible for taking incoming AC power—typically from a main panel or transformer—and routing it to multiple downstream devices. These can include control modules, fans, heaters, solenoids, lighting, and instrumentation.

The purpose of these boards is threefold:

-

Distribution: They distribute power from a single input to various outputs.

-

Protection: Circuit breakers or fuses protect each output from overcurrent or short circuits.

-

Organization: They provide a structured wiring layout, reducing clutter and simplifying maintenance.

In turbine systems, where operational uptime and safety are non-negotiable, these boards play a pivotal role in maintaining reliable power flow to essential equipment.

Key Design Elements

Designing a local AC distribution board for use in turbine systems involves careful consideration of both environmental and functional requirements. These boards must be robust, accessible, and engineered to meet high standards of electrical safety and reliability.

1. Power Input and Output

Typically, these boards accept three-phase AC input, often at voltages ranging from 120V to 480V. The output circuits are configured to supply power to both critical and non-critical loads within the turbine control panel.

2. Protection Mechanisms

Each outgoing circuit is individually protected using fuses or miniature circuit breakers. This prevents faults in one part of the system from affecting the entire power distribution network.

3. Indicator Features

Many boards include LED indicators or visual fuse status windows, enabling operators to quickly identify blown fuses or active circuits without needing to open or dismantle the enclosure.

4. Environmental Durability

Since turbine environments can be subject to heat, vibration, and dust, these boards are built with industrial-grade materials and are typically mounted inside sealed or filtered enclosures.

5. Mounting and Integration

The layout is often DIN-rail compatible, allowing easy integration into existing turbine control cabinets. Terminal blocks are arranged for clear labeling and quick wiring during installation or servicing.

Functionality in Turbine Applications

Within a turbine system, the local AC distribution board powers a wide range of devices that are vital to operation and monitoring. These include:

-

Controllers and PLCs: Supplying clean and reliable AC power to the turbine’s brain.

-

Field Devices: Energizing actuators, solenoids, and motorized valves used in fuel, air, or steam flow regulation.

-

Environmental Controls: Powering fans and heaters to maintain optimal cabinet conditions for sensitive electronics.

-

Lighting and Auxiliary Loads: Supporting maintenance lighting or small tools within the control enclosure.

The power board also helps segment power zones—separating critical from non-critical loads. This ensures that in the event of a partial failure, essential operations can continue unaffected.

Maintenance and Operational Considerations

Effective turbine operation requires that these boards are regularly inspected. Maintenance typically includes:

-

Tightening terminal connections

-

Checking for signs of overheating or wear

-

Verifying the integrity of fuses and breakers

-

Ensuring LED indicators are functioning correctly

By conducting preventive maintenance, operators reduce the risk of power interruptions or equipment damage caused by undetected faults.

Conclusion

Local AC power distribution boards are fundamental to the safe and efficient operation of turbine control systems. By organizing power flow, isolating faults, and enabling easy maintenance, these boards ensure continuous operation in demanding industrial environments. Whether powering critical control electronics or auxiliary support devices, their role in turbine systems is both indispensable and often underappreciated.