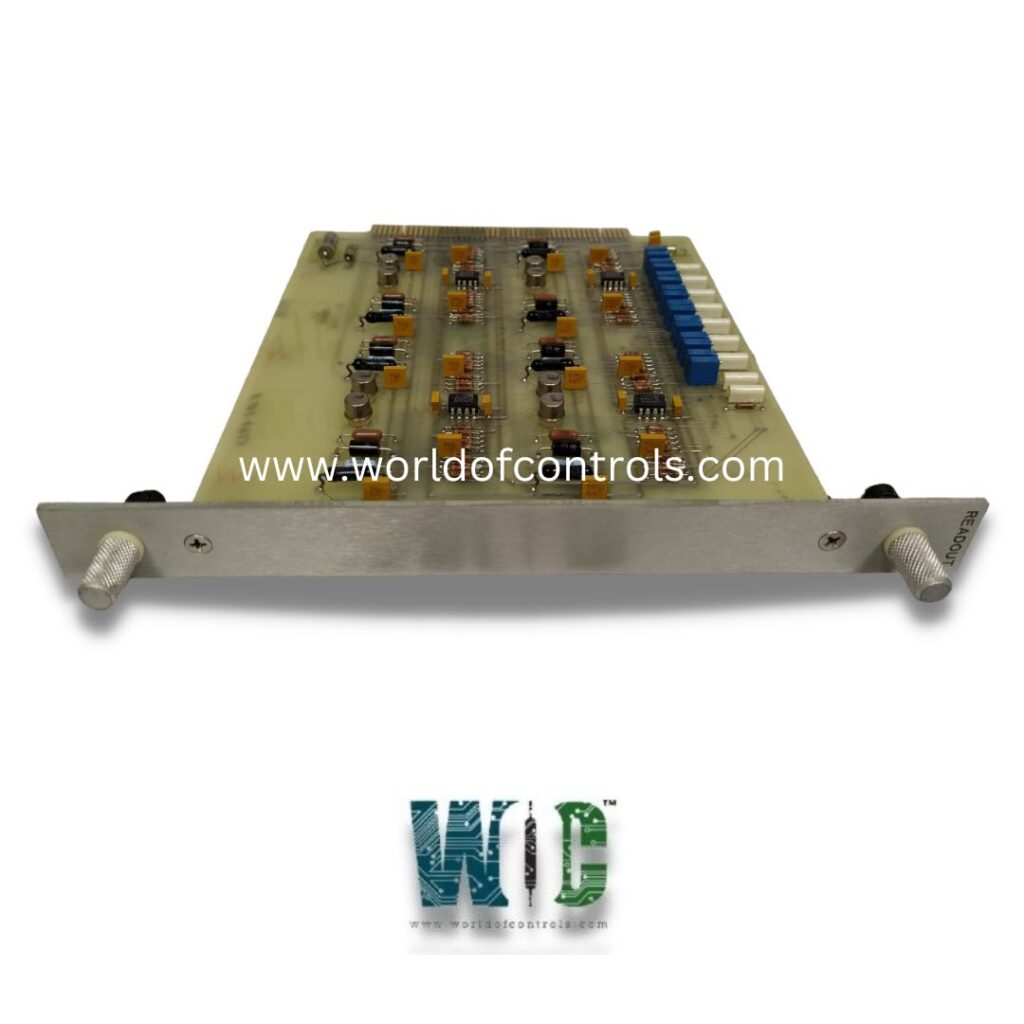

5463-340

In the turbine industry, where performance, reliability, and safety are paramount, the ability to monitor and manage control systems in real time can make a significant difference. Woodward, a trusted name in industrial control solutions, offers a range of readout modules designed to bridge the gap between complex control systems and human operators.

These modules are more than just display tools—they are essential components in optimizing turbine performance and minimizing downtime.

Boost turbine performance with Woodward readout modules—real-time monitoring, faster decisions, and improved operational efficiency

What Are Woodward Readout Modules?

Woodward readout modules are interface devices that connect directly to turbine control systems. Their primary function is to provide real-time feedback on system parameters such as speed, load, temperature, and pressure. This data is made accessible through visual displays—typically LED or LCD panels—located on or near the control cabinet.

By presenting critical information in a clear and accessible format, readout modules allow operators to monitor turbine health at a glance. This is particularly valuable in high-stakes environments such as power generation, marine propulsion, and oil & gas applications, where every second of downtime counts.

Why Monitoring Matters in Turbine Operations

Turbines operate under extreme conditions and are subject to dynamic changes in load and environmental factors. This makes continuous monitoring essential for safe and efficient operation.

Readout modules contribute to this by enabling:

- Immediate visibility of operating conditions

- Early detection of performance anomalies

- Quick response to system alarms or warnings

- Reduced dependence on remote diagnostics or SCADA systems in field environments

Enhancing Operational Efficiency with Local Monitoring

1. Real-Time Decision Support

Operators often work in fast-paced environments where waiting for data from a central control room isn’t practical. Woodward’s readout modules offer on-the-spot decision-making capabilities by displaying real-time data locally. This leads to faster response times and more agile operations.

2. Reduced Downtime through Predictive Maintenance

With accurate parameter readings available instantly, maintenance teams can spot trends and anomalies that indicate potential component wear or failure. This supports a predictive maintenance approach, which is far more cost-effective than reactive repairs after a breakdown.

3. Simplified Training and Operation

The modules are designed with user-friendly interfaces, requiring minimal training. Technicians and operators can quickly learn how to read and interpret system data, reducing the learning curve and improving team efficiency.

4. Improved Safety and Compliance

By giving operators direct access to critical safety parameters, such as turbine overspeed or excessive exhaust temperatures, the modules help maintain compliance with safety standards. They also support faster shutdown or correction in emergency situations, minimizing risks to equipment and personnel.

Versatility Across Turbine Applications

Woodward readout modules are commonly used in:

- Steam and gas turbine control systems

- Hydropower generation plants

- Marine propulsion systems

- Industrial cogeneration and backup power units

They can function as part of both modern digital control architectures and legacy systems, making them ideal for plants undergoing upgrades or operating in hybrid environments.

Bridging Legacy and Digital Control Systems

In many facilities, turbine controls are gradually being modernized. Readout modules offer a valuable intermediate solution—allowing continued use of legacy systems while integrating with newer technologies such as programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems.

This modular and scalable approach supports long-term digital transformation without disrupting existing operations.

Conclusion

Woodward readout modules play a vital role in improving the efficiency, reliability, and safety of turbine operations. By enabling real-time visibility into system performance, they empower operators to make quicker, smarter decisions and reduce both planned and unplanned downtime.

Whether you’re managing a legacy power plant or moving toward a fully digital infrastructure, incorporating these modules into your turbine control strategy is a practical step toward operational excellence.