Introduction

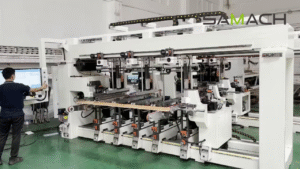

In an era where automation and precision define competitive advantage, SAMACH stands out as a global leader providing woodworking machines, including highly sophisticated edge banding machines. Their forward-thinking designs, combined with versatile applications across industries, make them an ideal partner for furniture makers, cabinetry specialists, and panel manufacturers seeking both quality and efficiency.

SAMACH: Crafting Intelligent Woodworking Solutions

SAMACH offers a comprehensive suite of woodworking machines, spanning wood-based panels machinery, solid wood machinery, and metal processing machinery. Their commitment to innovation is evident in the intelligent solutions they provide for contemporary furniture manufacturing.

The Art of the Edge Banding Machine

What Is Edge Banding?

Edge banding is a finishing process where a narrow strip of material—such as PVC, ABS, wood veneer, or melamine—is applied to cover exposed edges of plywood, particle board, or MDF. This improves both aesthetics and durability of panels.

The Role of an Edge Banding Machine

An edge banding machine automates this process: it bonds the edging material to the substrate, trims excess, flushes edges, scrapes surplus adhesive, and performs a final buff for a clean finish.

SAMACH’s Edge Banding Machine Portfolio

SAMACH showcases an extensive line of edge banding machines, each tailored to specific production needs:

-

Full Automatic Edge Banding Production Line

-

High Speed Edge Banding Machine

-

Automatic Inclination & Straight Edge Banding Machine

-

J-Shaped Edge Banding Machine

-

EVA Glue and PUR Glue Edge Banding Machine

-

Solid Wood Strip Edge Banding Machine

-

Small Edge Banding Machine, including mini and inclination variants

-

Curve & Linear Edge Banding Machine, including bevel curve versions

-

CNC Curve Edge Banding Machine

-

Series-based machines like 465 and 565.

Spotlight: Small Edge Banding Machine

SAMACH’s Small Edge Banding Machine offers six integrated functions and incorporates durable, Taiwan-brand end trimming guide rails and a well-known Taiwan touch-screen PLC control system. Specs include:

-

Panel length: ≥ 90 mm

-

Panel width: ≥ 55 mm

-

Panel thickness: 10–40 mm

-

Edgeband thickness: 0.4–2 mm

-

Feeding speed: 18 m/min

-

Power consumption: 6 kW (models RE-S1 & RE-S2), 9.6 kW (RE-S3)

-

Size & weight vary by model

These compact yet powerful units are ideal for small workshops and manufacturers needing edge banding precision without the scale or footprint of full-production lines.

Advantages of SAMACH Edge Banding Solutions

-

Automation & Efficiency: Their fully automatic lines and high-speed machines are designed to keep pace with large-scale production demands, delivering high throughput with minimal manual intervention.

-

Versatility & Customization: Whether you require EVA or PUR gluing, curved edge banding, or specialized J-shapes, SAMACH’s diverse lineup covers a wide array of manufacturing scenarios.

-

Smart Controls & Durability: Utilizing reputable component brands (e.g., Taiwan-developed PCs/PLCs and precision guide rails) ensures consistent reliability and user-friendly operation.

-

Tailored Solutions for Working with Wood: Dedicated machines for solid wood strip edging and CNC-enabled edge banding empower manufacturers to tackle complex woodworking joins and contours with ease.

Integrating Edge Banding Machinery into a Modern Woodworking Production Line

A comprehensive woodworking machine lineup might look like this:

-

Panel Saw: Ensures precise sizing of wood materials.

-

CNC Router: Enables intricate shaping, carving, and hollowing work.

-

Edge Banding Machine: Delivers efficient finishing, concealing raw edges while enhancing durability.

-

Membrane Press Machine, Painting Machine, Sanding Machine: Round out panels for polished surface treatment.

This sequential flow—from cutting to finishing—reflects a lean, intelligent furniture-production ecosystem, with SAMACH equipment forming the backbone.

Why SAMACH Stands Out

-

Comprehensive Product Range: From compact edge banding units to large-scale production lines, SAMACH caters to diverse workshop sizes and functionalities.

-

Global Expertise: SAMACH operators boast a strong R&D and manufacturing team with international exposure and capability.

-

Export-ready Offerings: Their edge banding machines—categorized by price and specification—are available on platforms like Alibaba, ranging from mini automatic units (~US $4,150–4,350) to high-speed edgebanders (~US $38,500–39,500).

Practical Use Cases

-

Industrial Furniture Makers: High-speed and full-automatic edge-banding lines meet mass-production deadlines while preserving quality.

-

Boutique Woodworking Shops: Compact models like the Small Edge Banding Machine ensure precision without occupying much floor space.

-

Specialized Design Studios: Machines capable of bevel and curve edge banding enable creative, non-standard piece fabrication.

-

Enterprise-level Manufacturing: End-to-end lines—from panel sizing to finishing—can be built using a suite of woodworking machines from SAMACH, making them turnkey partners for factory automation.

Conclusion

SAMACH’s robust and flexible woodworking machines, especially their intelligent range of edge banding machines, present compelling advantages: automation, precision, adaptability, and durability. Whether you’re a small-scale shop or a large-scale furniture factory, SAMACH provides machinery and support to elevate your productivity and craftsmanship.

By choosing SAMACH, you’re not just investing in equipment—you’re integrating intelligent solutions designed to shape the future of woodworking.